Over the last several years, factory fires have ranked as one of the most common types of disruptive supply chain events: in 2020 1,000 factory fires were tracked by Resilinc’s EventWatch monitoring system. However, fires that occur far outside factory gates are becoming a greater concern for supply chain risk managers. As recently covered by Supply Chain Dive, wildfires have in recent years cut off the major highways I-5 and I-15 in California. “Sometimes they’re cut off for a week at a time,” said B.J. Patterson, CEO of 3PL Pacific Mountain Logistics, adding that freight railroads using these corridors have also been shut down due to fires.

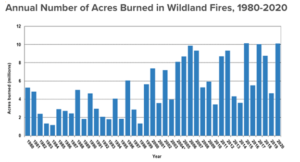

According to the National Interagency Fire Center, wildland fires have occurred with increasing frequency in the U.S. over the last 20 years, with 2015, 2017 and 2020 seeing more than 10 million acres burned (see below chart). In the Western United States, drought conditions have made 2021 more fire prone than any year in history—with 28,200 wildfires reported as of June 17, a 30% increase over the same period in 2020, according to the Insurance Information Institute.

Wildfire risks are increasing across much of the planet, often linked to droughts. As an example, Australian bushfires burned more than 46 million acres in less than six months during the southern hemisphere’s 2019-2020 fire season. In addition to doing physical damage and disrupting logistics, wildfires can also impact agricultural production in fire-prone regions. The bushfires devastated milk production in Victoria and killed US$2.4 billion worth of livestock, according to Everstream Analytics.

Climate change is expected to worsen droughts and wildfires in many regions. Global cotton supplies are considered especially vulnerable to worsening droughts, heat waves, and wildfires, according to a new analysis by climate risk consultancy Acclimatise, which is part of risk management and insurance firm Willis Towers Watson.

The Cotton 2040 report finds that half of global cotton producing regions will be at greater risk by 2040. While cotton is only a $12 billion industry, it makes up 31% of raw materials used in the textile and apparel industries, which have a global economic impact of $600 billion according to the report.

While tackling climate change is a long-term challenge, there are measures that supply chain managers can take today to improve the resiliency of their supply chains to wildfires. The foundational practice to build resiliency to wildfires and all types of disruption is to improve your organization’s visibility into your supply chain through supplier mapping. Knowing which of your suppliers are in the areas vulnerable to bushfire-related disruptions allows supply chain managers to quickly assess potential impacts, delays, ripple effects, and initiate emergency responses.

Although fire seasons are starting earlier and lasting longer in many regions, there is still seasonality to fire risk, and this allows for proactive risk mitigations. With an accurate map of the supply chain, managers can assess what suppliers, logistics nodes, and shipping routes are at elevated risk and initiate risk mitigations. One method is to proactively move some inventory out of the region or add buffer stock outside the fire-prone region. Resilinc also recommends considering contingent business interruption insurance for fire-vulnerable sites in supply chains, including 3PL providers and contract manufacturers.