What a winter it’s been! The US has seen extreme storms from coast to coast (yes, even in typically sunny California), proving that you can’t predict the weather. In February alone, there were multiple winter storms. In fact, on February 21st, Resilinc tracked three, separate winter storm warnings for the Southwest, Northern Great Lakes, and Parts of New England — across all these regions over 45,000 supplier sites were potentially impacted by the weather!

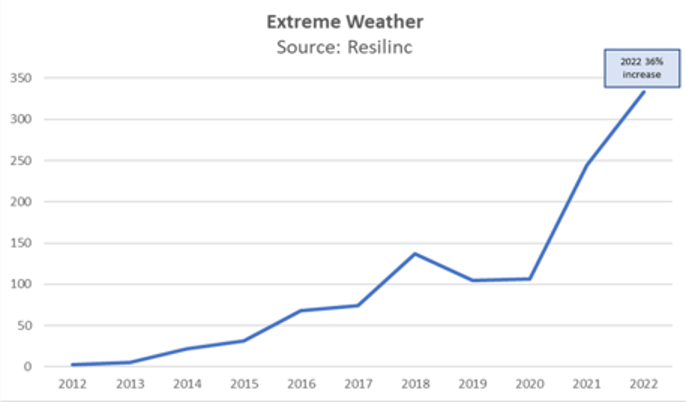

Weather related events show no signs of slowing down, either. Our 24/7 event monitoring platform, EventWatchAI sent alerts for 333 Extreme Weather events in 2022; this was up 36% YOY. According to our data, Extreme Weather was the 11th highest reported disruption in 2022. (Side note: we track alerts for Hurricanes/Typhoons and Floods separately; both of these events were up 18% YOY and 36% YOY respectively.)

While you can’t predict the weather, that doesn’t mean you can’t buy a snow shovel or a raincoat to prepare for it and mitigate the impact. The same is true for your supply chain. When severe weather strikes, it’s often too late to “go shopping for supplies”. Having a proactive plan in place (instead of a reactive one) is key to surviving and thriving when severe weather strikes.

In this blog, we’ll discuss how you can prep for severe weather by building a more resilient, weatherproof supply chain in seven steps.

#1 Map Your Supply Chain (Multiple Tiers Deep)

85% of disruptions occur in the lower tiers of your supply chain. If you don’t know where your suppliers are located or where your parts come from, you’ll likely be behind the supply chain resiliency curve when severe weather strikes.

Take this example: when category 5 Hurricane Maria was approaching Puerto Rico in 2017, suppliers and critical FDA-regulated materials were threatened.

Through multi-tier mapping, Resilinc was able to identify which suppliers and parts would be affected. With this visibility, our customers initiated a dual-sourcing effort to secure supplies ahead of time. One customer in particular successfully secured $1.5 million worth of IV bag inventory (at the time Puerto Rico was the sole source of these bags for the majority of US-based healthcare providers). By identifying and mapping single source constrained raw materials in advance, Resilinc helped our customer avoid supplier shortages, meet patient needs and revenue targets.

Weatherproofing your supply chain starts with knowing where your parts come from.

Consider this: the inability to secure a part costing $0.01 can impact a billion dollars in revenue. If a storm strikes the site where this small-but-essential part is produced and you’re unaware, it could mean lines down and a disruption to business continuity. Worse, it could mean an end user, like a patient doesn’t get the resources they need. This can be disruptive to your business for several reasons:

- If you don’t have a backup plan, it can be time-consuming and costly to find an alternative supplier with such short notice. Odds are, if you’re looking for an alternative supplier, so are other companies. Not only will it be difficult to secure an alternative, but prices will most likely be higher than usual due to increase competition.

- If you’re unable to secure an alternative part, you might have to wait until production can resume. While you are waiting, your competitors may see increased sales from the products you are unable to produce and sell during this time.

- If you can’t secure a certain part, it may slow down other parts of your manufacturing — or worse, bring your manufacturing to a standstill. For example, the chip shortage caused cars, that were otherwise finished, to sit in parking lots until the chips could be produced. This simultaneously increased the cost of storage for the cars that could not be sold.

By mapping your supply chain, you’ll gain the visibility you need to proactively move high-risk products out of areas, find alternative sites, and pivot before extreme weather strikes. Learn more about the different ways to map your supply chain.

#2 Invest in Event Monitoring

Monitoring gives you a real-time pulse on any events that could potentially pose a threat — and there are a variety of technology-based supply chain risk-monitoring services available on the market.

So, how can you choose which one is best for your monitoring needs?

The difference comes down to the number of sources monitored, the quality of the data collected, and the timeliness of the data. As an example, Resilinc’s EventWatchAI scans over 100M sources and sites for worldwide potential disruptions that can affect you and your supply chain. Resilinc identifies impacts in over 100 languages, 200 countries, and 50 event types (including severe weather) to tailor alerts and suggest actions specific to your unique business.

While our AI monitors internet and social media 24×7, we find and validate developments that influence your supply chain operations, so you don’t have to. Each user sets their own preferences for personalized, industry-related alerts via web, mobile, and API. Powerful collaboration tools then accelerate response and recovery efforts on your path to proactive risk mitigation.

Investing in Event Monitoring is crucial to weatherproofing your supply chain, so you can get real-time updates and act quickly.

#3 Assess Supplier Risk

Are your suppliers prepared to weather a severe storm or hurricane? By sending out ongoing supplier risk assessments directly to your suppliers you’ll be able to gauge readiness across their sites. As an example, Resilinc offers a Hurricane Readiness assessment that asks questions like:

- Is your manufacturing or processing site equipped with a satellite phone?

- Are you taking steps to move 2-3 weeks of inventory outside the hurricane region to protect your customers from disruption?

- Do you have fuel replenishment contracts to ensure back up power can remain operational?

Next, highlight your suppliers that have strong practices in place. You can use these suppliers as a benchmark to evaluate weaker suppliers. On the same note, pay attention to your at-risk suppliers and work with them to develop a plan to close the gap. As they make progress towards stronger weather-readiness, maintain active tracking and report on their progress. If for some reason the risk is too great for certain suppliers, it may make sense to terminate the relationship and find a new supplier.

Interested in sending ongoing supplier risk assessments? See how Resilinc’s RiskShield and our Supplier Assessment Library can help.

#4 Analyze Past Disruption Data

Do certain sites frequently experience disruptions due to severe weather? Analyze past disruption data to identify links in your supply chain which are most vulnerable to future weather events. Looking at past data, can help you identify when future weather events may occur, and can help you see why a disruption occurred in the past.

Often if a disruption occurred in the past, it is a good indicator that site may lack robust continuity plans. Resilinc data shows that suppliers who are most seriously disrupted by extreme weather are typically the least prepared, so use this an opportunity to uncover weaker suppliers and identify continuity problems to weatherproof your supply chain.

#5 Offer Incentives to Suppliers

After you identify your strongest (and weakest) suppliers through sending supplier risk assessments, you will have a better idea which practices lead to increased weather resilience. From there, you can offer incentives to suppliers that invest in mitigation measures such as backup power generation and satellite telecom capabilities.

One Resilinc survey of suppliers’ business continuity plans revealed that 37% of suppliers had no backup power and 73% had no satellite phone—both of which are essential to continuing operations and communicating with customers during the power outages that are frequently caused by heavy storms.

If you learn that your supplier is lacking these critical resources, you can offer incentives that encourage your supplier to invest. Some Resilinc customers have even used their Resilinc supplier risk management tools to create standards for suppliers and have even agreed to pay more for materials in exchange for their suppliers investing in risk mitigation measures.

For more on collaborative risk management in supply chains, see this post: Why Supplier Collaboration is a Win-Win Strategy.

#6 Create a Logistics Backup Plan

Severe storms can cause power outages and close roads. Do you have a logistics backup plan?

- Plan to hold extra inventory at other sites.

- Have alternative distribution methods (i.e. trucks, trains, planes, alternate ports)

- Don’t rely on 1 site for high-risk parts if possible

- Develop a playbook for dealing with severe weather

#7 Utilize AI Predictive Analytics

Sometimes it snows in April. Despite your best efforts to plan ahead, it’s inevitable that some supplier sites and logistics routes will remain vulnerable to severe weather — and unexpected weather events can always happen.

So, what can you do before the unexpected happens?

Invest in predictive analytics capabilities that help you respond quickly and adapt to severe weather events before or as they unfold. The way to achieve this is by leveraging AI and machine learning to ultimately reach a level of automation where decisions are made, based on data by machines, in a split second.

For example, Resilinc’s Predictive Purchase Order (PO) on-time delivery solution uses AI to identify how a supplier will perform in the face of a disruption by analyzing past events and on-time delivery data. The first-of-its-kind prediction tool leverages AI, historical data, and machine learning to: send alerts about a new, potentially disruptive event anywhere in the world; predict impact likelihood; predict which suppliers are most at risk of delivering late, and by how long; and identify how affected suppliers will perform and propose a risk-mitigation action plan.

Using this tool, organizations can plan for and mitigate risk before disaster strikes, protecting continuity of supply and avoiding execution delays

Is Your Supply Chain Weatherproof?

Through gaining visibility into your supply chain, connecting with your suppliers, and planning ahead, you can see when disruptions are likely to occur, the potential impact of the disruption, and act quickly to mitigate lost revenue.

With weather-related events up 130% from 2020 to 2021, now is the time to invest in technology-based supply chain risk management tools to stay ahead of severe weather!

Have any other questions about weatherproofing your supply chain? Reach out to see how Resilinc can help.