We’re already over halfway through 2023, and things are looking up for the supply chain. We dug into the data from our event watch monitoring platform, EventWatchAI, and here’s what we found. From January to June, we saw a total of 8,197 supply chain disruptions, only a 3% year-over-year increase. This ever-so-slight increase hints that the supply chain is stabilizing—which is great news considering how volatile the past few years have been.

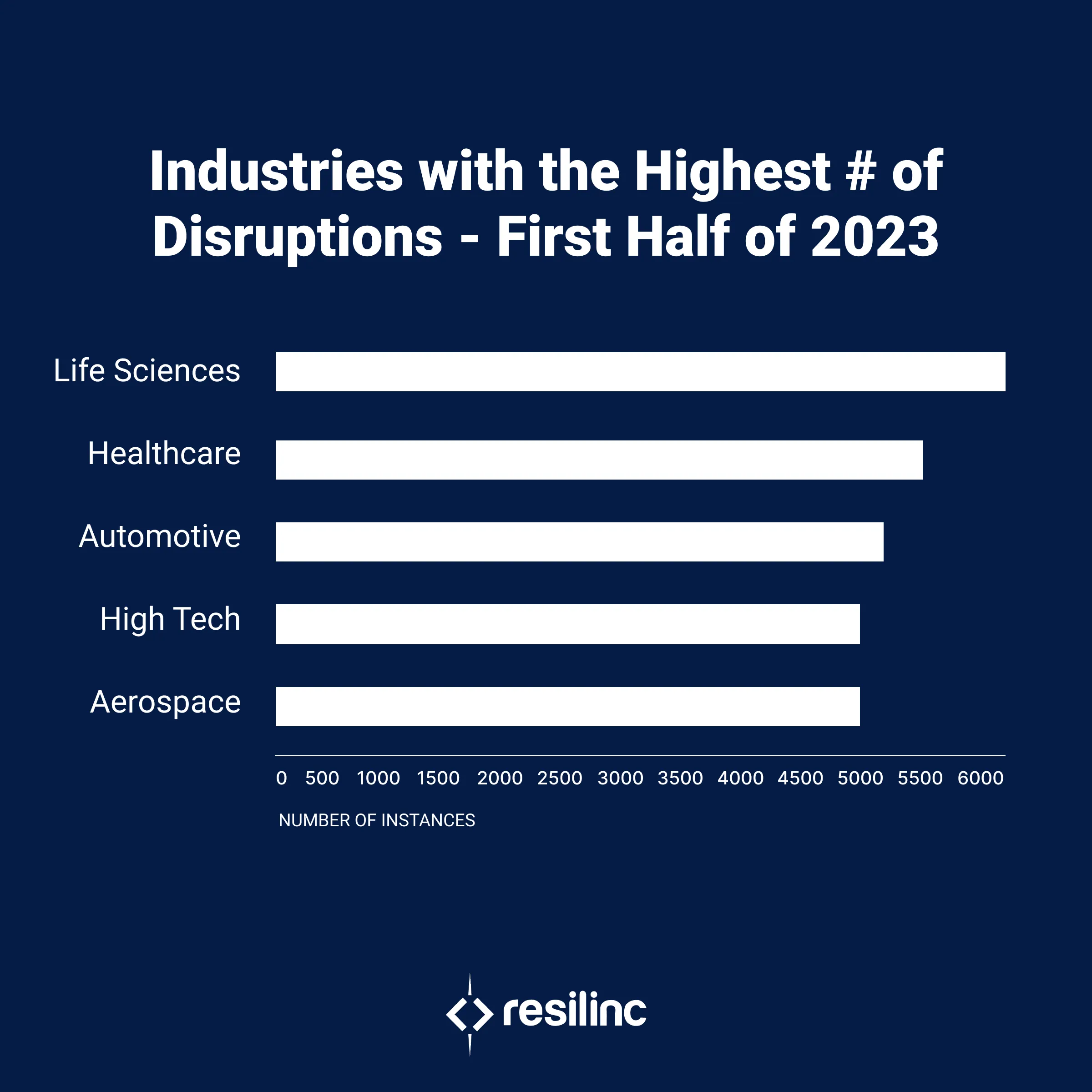

But, as we know in supply chain, even though things are starting to level out, supply chain disruptions are still happening (and always will be!). The industries experiencing the most disruptions for the first half of the year include life sciences, healthcare, high-tech, automotive, and aerospace. Below we take a closer look at the top 10 supply chain disruptions that impacted these major industries for the first half of 2023.

#1 Factory Fires

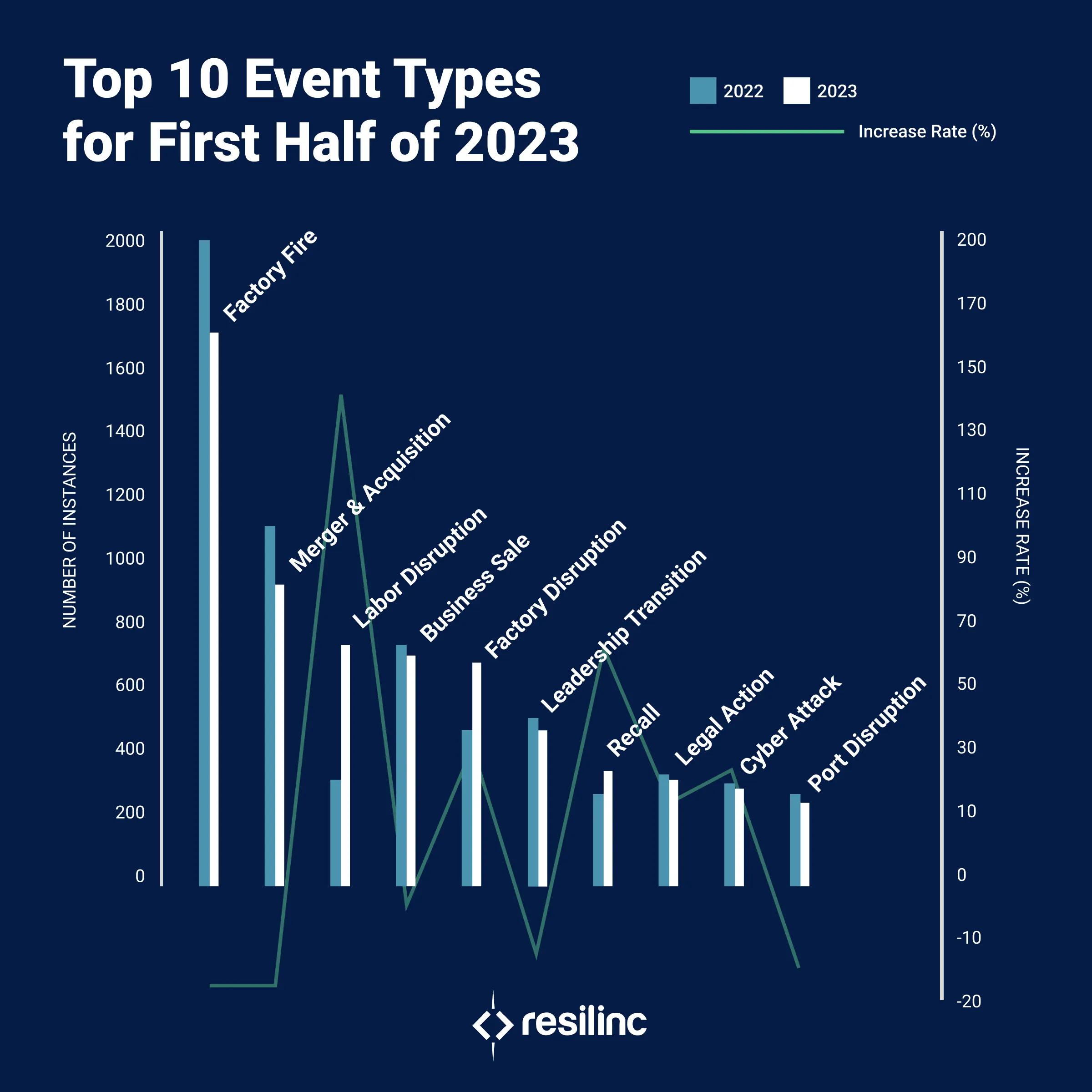

While still the leading supply chain disruption, with 1,642 notifications in the first half of the year, Factory Fires actually experienced nearly a 20% decline year-over-year. This is the first time in five years that we have seen a decline in Factory Fires. Why the big shift?

Resilinc CEO and Co-Founder, Bindiya Vakil had this to say about the increase in factory fires during and after the pandemic, “Factories need to be kept clean, free of debris near the hot work areas. There needs to be constant inspection of electrical systems and machinery and things like that. This is one of those things that’s the outcome of COVID.” Post-covid, factories have been able to restore proper maintenance and procedures. Decreases in production due to shifting consumer demands have also helped contribute to the recent decline in factory fires.

#2 Mergers & Acquisition, #3 Business Sale, and #4 Leadership Transition

Financial and organizational risk areas such as Mergers & Acquisitions, Business Sale, and Leadership Transition remained among the top five disruptions, but displayed signs of stabilization and slight deceleration compared to the first half of 2022. Business Sale disruptions only saw a 4% decrease, while Leadership Transition disruptions decreased by 11%.

Merger & Acquisition disruptions decreased by 17%, but there were still notable M&A’s in 2023 such as Amgen’s acquisition of Horizon Therapeutics for $26.4 billion and L3Harris acquisition of Aerojet Rocketdyne for $4.7 billion. If you’re curious to learn how M&A’s impact the supply chain, check out Resilinc’s blog: How Do Mergers and Acquisitions Impact Supply Chains?

#5 Factory Disruption, #6 Legal Action, and #7 Labor Disruptions

In the first half of 2023, EventWatchAI sent out alerts for 569 factory disruptions. Factory disruptions, including shutdowns, production halts, warnings/citations, and labor accidents, increased by 30% year-over-year. Legal action saw an 11% increase year-over-year.

Labor disruptions were substantially higher this year—up an astounding 136%. This includes company and site-level strikes, national strikes (like the Labor Union strikes in France or the worker walkouts at Starbucks in the U.S.), layoffs (like this year’s job cuts at Google, PayPal, Meta, and Amazon), and labor protests, among others.

#8 Cyber Attack, #9 Port Disruptions, and #10 Recalls

Cyberattacks saw a 24% increase from the first half of 2022. Cyber Attacks have been steadily increasing over the past few years. In the first half of 2019, there were only 28 total cyberattacks detected by EventWatchAI, but so far this year, we’ve seen 341 cyberattack disruptions, including a data breach in the US Department of Transportation and a cyberattack against the parliament of Sweden. To learn about notable cyberattacks and best practices for your company to mitigate risk, check out our special report IoT in Supply Chains: Latest Cybersecurity Risks and Top Solutions.

Port disruptions saw a slight 13% decrease. This is another sign that the supply chain is stabilizing, considering that global port disruptions were up 40% in 2022. In 2022, Covid-19 lockdowns and restrictions, as well as inflation, resulted in port shutdowns, increased shipping costs, and supply chain blockages.

Recalls surged by 66% compared to the first half of 2022. Many of these recalls came from the top affected industries: life sciences and healthcare. Some of the biggest medical device recalls of 2023 include Smiths Medical’s recall of 20 million in medical devices and GE HealthCare’s recall of 688 body scanners. Automotive also saw significant recalls. Ford recalled over two million cars, Nissan nearly 1.9 million, and Honda recalled nearly half a million vehicles.

Stay Ahead of Disruptions for the Last Half of 2023

While the supply chain is stabilizing, this doesn’t mean supply chain managers can stop monitoring risk. Businesses must continue to stay vigilant and plan ahead to respond quickly and effectively to ever-changing disruptions and risks.

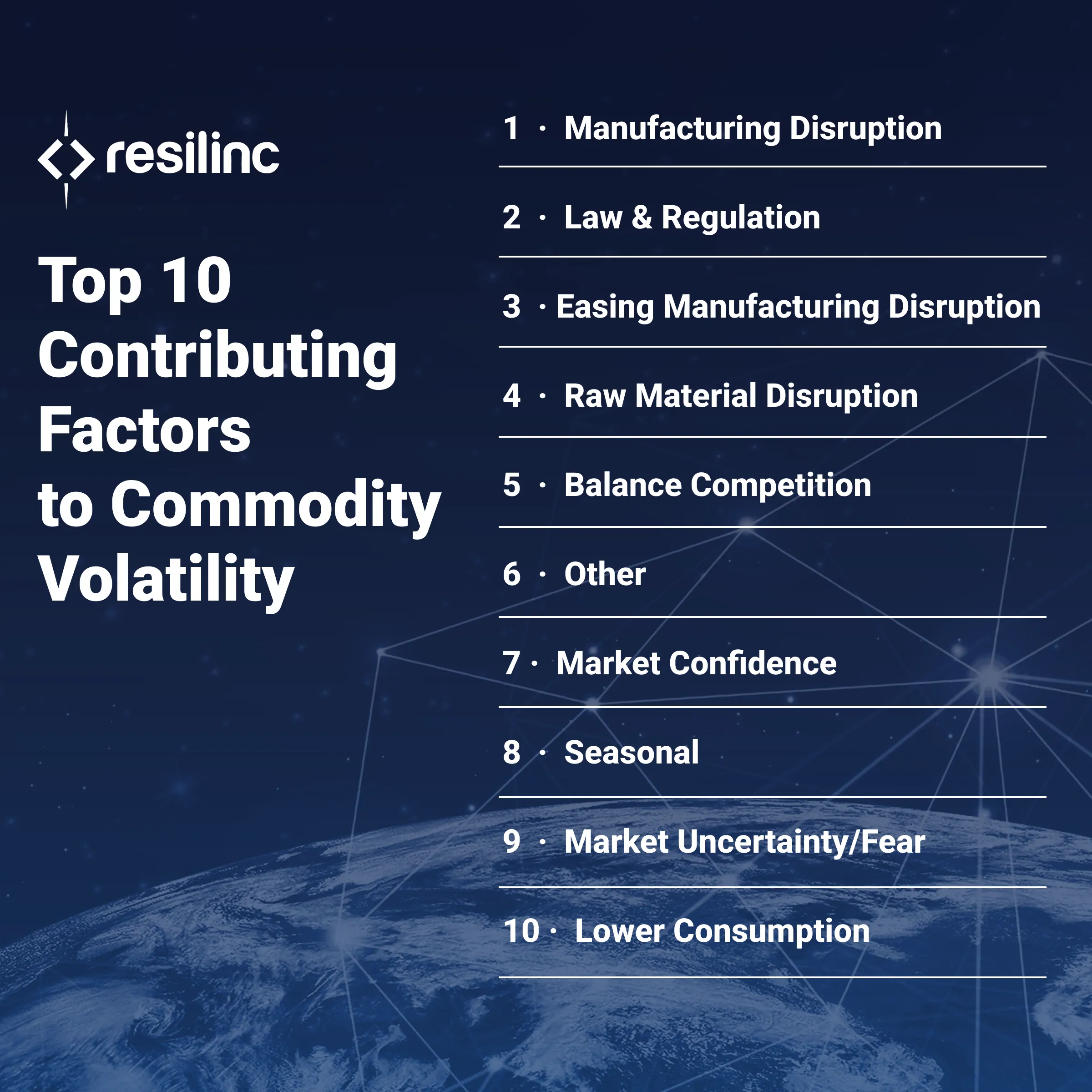

If your business relies heavily on specific commodities, Resilinc’s CommodityWatchAI platform can help you predict commodity price fluctuations and supply constraints more than three months out. Below is a look at the top 10 factors that contributed to commodity volatility in the first half of 2023. Navigate these fluctuations using a predictive algorithm which combines machine learning and Resilinc’s proprietary data—learn more about CommodityWatchAI here.

Stay on top of the latest supply chain disruptions too. Using Resilinc’s EventWatchAI 24/7 supply chain disruption monitoring system, companies can ensure they have the latest data in order to mitigate risk and make timely, informed decisions. EventWatchAI scans over 100M sources and sites for worldwide potential disruptions, identifying impacts in over 100 languages, 200 countries, and 50 event types. Customers are then sent tailored alerts and suggestions for actions specific to their businesses. Learn more EventWatchAI here.