Continued investment in semiconductor manufacturing was a resounding theme at the annual SEMICON® West conference, held July 9-11, 2024 at the George R. Moscone Convention Center in San Francisco.

Factors driving growth across the industry include:

- Global economic and political efforts, 64 countries have elections this year

- Market modernization driven by Cloud, generative AI, and quantum computing

- Increased focus on sustainability as energy consumption from semiconductor manufacturing is set to double by 2026

Additionally, increasing global regulatory compliance will continue to pose significant obstacles for manufacturers, as well as ongoing challenges like raw materials and labor shortages. How can the semiconductor industry adapt and evolve to overcome these challenges? Below, we dive into our top takeaways from SEMICON West to shed more light on the discussion.

Takeaway 1: Semiconductor infrastructure investment highlights from the CEO keynote summit series

Returning to the event this year, the CEO Summit keynote series focused on key investments made thus far in the global semiconductor industry. This series featured 16 unique sessions discussing the $225 billion in combined public and private investments committed to the industry. SEMI’s Joe Stockunas and Ajit Manocha kicked off the series by highlighting the industry’s expansive growth—with 104 planned fab investments through 2027, with the U.S. and Taiwan spearheading this expansion. Semiconductor is expected to move into a bull cycle with forecasts of industry revenue surpassing $1T by 2030 and $5T by 2040.

The summit also highlighted domestic investments during the “Investing in America’s Path Forward” session, which featured updates on the CHIPS Act and state support from government officials. Dr. Laurie E. Locascio, Director of the National Institute of Standards and Technology (NIST), projected that global chip demand will reach 28% by 2032. She laid out the government’s plan to expand beyond just fabs and nearshoring activity, to pre- and post-product supply chains. This shift would position the U.S. as a major player in the full-stream semiconductor value chain for advanced chipsets.

Kevin Youniss, COO of Empire State Development, also spoke of New York’s leading role in semiconductor investments, spotlighting Micron’s $100 billion megafab in central New York, expected to create nearly 50,000 jobs.

Takeaway 2: High energy consumption in high-tech and semiconductors driving sustainability efforts

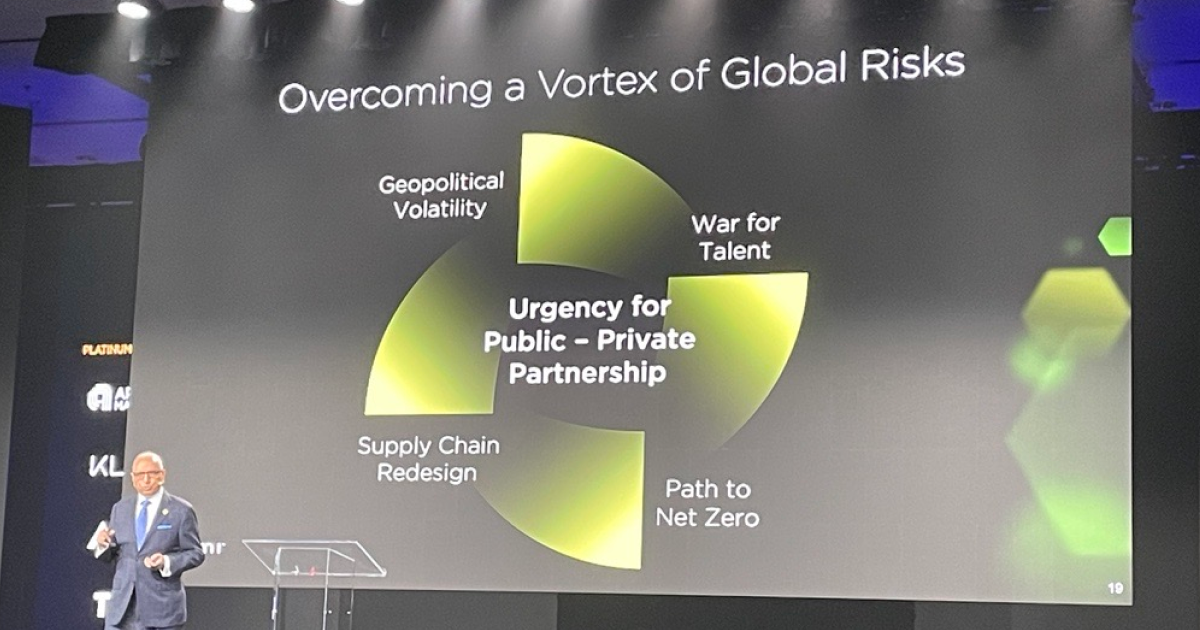

During the CEO Summit Day 2, “Seizing the Global Opportunities and Challenges Ahead,” speakers addressed pressing global semiconductor industry issues such as supply chain resilience and the need for semiconductor manufacturing to become more sustainable.

Former Vice President Al Gore explained that by 2026, energy consumption driven globally by the semiconductor industry and data centers will double. For the industry to continue growing, manufacturing processes must become cleaner and more sustainable. To make this sustainable movement possible, governments must be willing to support innovation.

Jeff Thomas, Executive Vice President of Corporate Platforms at NASDAQ, also discussed the semiconductor industry’s unique role as an exchange operator and provider of ESG-focused technology and marketplace solutions. According to Thomas, 90% of all publicly traded semiconductor companies are listed on the NASDAQ. Now, NASDAQ is creating a ChatGPT-driven solution that links its sustainability database of all publicly traded companies to activities and disclosures corporations have made on sustainability.

Takeaway 3: Smart Manufacturing is growing

With an entire five-part series dedicated to the subject, Smart Manufacturing was a hot topic at the event, comprised of such sessions as:

- Session 1: Digital Twins for Design & Manufacturing

- Session 2: Front-End Manufacturing – Optimizing Yield with AI

- Session 3: Back-End Semiconductor Manufacturing – AI for Smart Production

- Session 4: Accelerating Sustainability with Smart Manufacturing

- Session 5: Automation & Equipment Toward Fully Autonomous Factories

According to TechTarget, Smart Manufacturing is “a technology-driven approach that utilizes Internet-connected machinery to monitor the production process.” By using Smart Manufacturing, companies can automate operations and improve efficiency.

As megatrends like globalization and climate change continue to drive innovation demand, Smart Manufacturing is expected to see increased investment over the coming years. Industrial industries such as oil and gas, automotive, and aerospace and defense are no strangers to the use of digital twins or smart factories. However, expanded adoption of these skillsets into other sectors of manufacturing will be in high demand for manufacturing workforces worldwide. Stay tuned for our upcoming manufacturing spotlight report.

Takeaway 4: Supply chain transformation beyond tier mapping

Over the last decade, companies invested millions in transforming supply chains, with significant efforts accelerated over the last four years by the pandemic. However, companies must go beyond sub-tier mapping and risk management to achieve true resilience. In a session moderated by SEMI’s Bettina Weiss, “Beyond Tier Mapping – Creating a Robust and Resilient Supply Chain Risk”, panelists discussed the importance of transparency and visibility. Panelists shared key guidelines for how to go beyond tier-mapping, including:

- Designing NPI for resiliency and sustainability

- Partnering with technology developers and supply base to drive resiliency

- Getting access to high-quality data and information

- Doubling down on current resiliency programs and collaboration efforts

Companies often view supply chain risk management (SCRM) as a discretionary insurance expense. Yet, the most resilient organizations are finding the opposite to be true. Our own Chris Benham, spoke on this topic in the session, “Supply Chain Resilience: Practical Approaches to Creating Business Value,” during the “Foundations for a Resilient and Agile Supply Chain” track. Joined by panelists SEMI’s Bettina Weiss and Genpact’s George Thompson, they discussed the importance of resilience in driving real revenue growth, noting that the definition of resilience is unique to each industry.

Register for our upcoming webinar, “How to Move Up the Supply Chain Maturity Curve.” Join Resilinc’s CEO Bindiya Vakil and CPMO LeAnne Hester as they discuss steps that businesses can take to move up the supply chain maturity curve.

Takeaway 5: The skilled labor shortage in high-tech is real

By 2030, approximately 4 million manufacturing jobs are expected to remain open, with capacity to fill only about 2.1 million of them. This labor shortage is a pressing concern for the semiconductor industry, especially as the industry grows. At the event, SEMI dedicated a section of the conference to talent acquisition, on-site interviews, and job postings for highly skilled labor, such as photonics engineers, AI coders, and electrical engineers to help address the issues.

The labor scarcity issue is undeniably real, and semiconductor firms are taking proactive measures to address this challenge before it becomes a bigger problem in the future. By focusing on early recruitment strategies and fostering education and training programs, these companies aim to secure a workforce capable of meeting the demands of the fast-evolving technological landscape. It’s crucial for businesses to act now to bridge the growing gap between job opportunities and the availability of suitably skilled labor.

Keep the conversation on semiconductors going after SEMICON West 2024

SEMICON West 2024 highlighted the dynamic and rapidly evolving landscape of the semiconductor industry, offering critical insights and innovative solutions to its most pressing challenges. From significant infrastructure investments and sustainability efforts to the rise of smart manufacturing and the necessity of advanced supply chain resilience, this year’s event showcased the industry’s drive towards growth and innovation. Moreover, the skilled labor shortage remains a significant hurdle, underscoring the need for proactive measures in talent acquisition and development.

As we look to the future, collaboration, technological advancement, and strategic investments will be key to navigating the complexities of the semiconductor sector. Want to keep the conversation going? Learn why increasing semiconductor supply chain resilience and security is a global imperative in our podcast with our own Chris Benham, SEMI’s Bettina Weiss, and Genpact’s George Thompson.