Just over a month ago, Hanjin Shipping Co, the world’s 7th largest shipping and Logistics Company in the world, filed for receivership on August 31, 2016. Hanjin Shipping Co. bankruptcy caused a major impact not just to logistics and shipping, but to the underpinning global supply chain and its sourcing operations. It has left nearly 80 ships with almost 500,000 containers offshore, with goods worth over $14 billion marooned at sea. The event, considered one of the biggest bankruptcies ever filed by a shipping company, has a disruptive domino effect on the supplier-dense regions of the world, in turn affecting supplier health and sourcing operations.

In its first quarter of 2016, Hanjin Shipping reported a net loss of $233.6 million on sales of $1.59 trillion won. By 2015-end, the company faced a debt of $5 billion as steep industry downturn squeezed profit margins. While overcapacity has significantly impacted the shipping industry, many other global factors have contributed not only to Hanjin’s financial crisis, but an industry-wide concern. These factors include:

- A weakened global GDP

- Multi-year Eurozone crisis

- Bloated US retail inventories

- Changing consumer spending patterns

- Meltdown of Chinese economy

- Muted demand for container shipping

Impacted Shipping Routes will impact Global Sourcing Operations

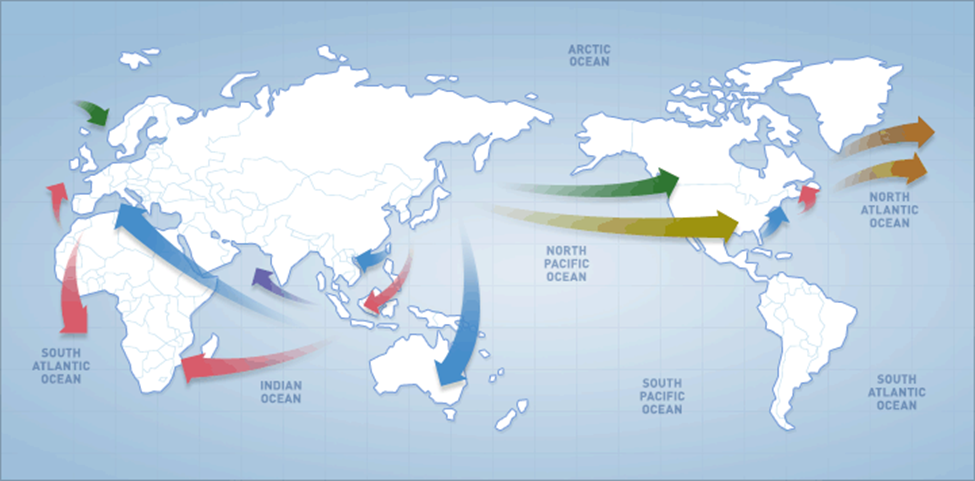

Hanjin Shipping Co. operates on 60 service routes in 35 countries, connecting more than 90 major ports and 6,000 destinations around the world. With Hanjin’s assets frozen, companies across the world are struggling to not only to retrieve their marooned goods on schedule and budget, but evaluate their ability to provide to their customers as well.

(Source: Hanjin company website)

While nearly every global industry, from retail to banking, can invariably feel the ripples from Hanjin’s bankruptcy, it is high time for supply chain practitioners to consider the bankruptcy’s impact to sourcing operations, particularly three key industries which rely on an increasingly interconnected, interdependent, and regionally dense supply chain network: Automotive, Life Sciences, and High-Tech.

The bankruptcy has created shipping and delivery uncertainties of which recovery times could take months. Rising competition amidst global shippers and a lack of alternatives have led to skyrocketing prices, causing financial distress to in the East Asia region.

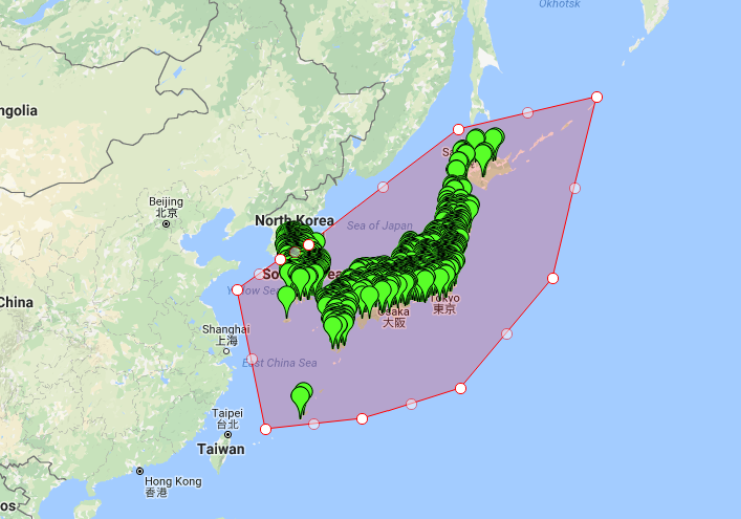

(Source: Resilinc Solutions)

Impact to the automotive industry – With critical supplier-dense regions throughout the world, the automotive supply chain is the best example of a truly international and interconnected supply chain. Rising prices amidst Hanjin’s bankruptcy can cause strains to material and part-level suppliers that are key to the successful production and delivery of an automobile.

Impact to life sciences – Constrained shipping opportunities can affect the ability of key material suppliers to deliver in a timely fashion. Unavailability of resources may force suppliers to launch their business continuity plan to brace themselves from severe economic impact

Impact to high-tech sector – According to the WSJ, freight brokers in Asia state that more than 540,000 containers are expected to face delivery delays from a few days to a few months. Asia being a prime source for high tech parts, production and manufacturing operations can be affected by widespread delivery delays.

The Ripple Effect – Impact on Supply Chain

Hanjin’s bankruptcy put seasonal inventory in limbo and has forced suppliers to begin re-evaluating import strategies– including high-cost options like airfreight — to mitigate potential supply chain interruptions. The indirect impact can also affect Tier-2 suppliers facing overcapacity issue due to amassing inventory. Industry experts suggest any claims to Hanjin could take up to 10 years to be settled. If Hanjin is liquidated, the economy of numerous creditors will be affected as a substantial part of creditors’ claims won’t be recovered. On a global level, a growing need for expedited transportation solutions has risen in the supply chain to avoid sourcing issues that could hamper supplier health.

Amidst wide scale disruption, there are several proactive measures companies can take to brace themselves:

- Review or create contingency plans to address your organization’s specific concerns

- Leverage supply chain mapping and analytics solutions to find out which of your suppliers are involved or potentially impacted by the bankruptcy. By opening communication channels, your company can identify how suppliers are monitoring financial risk scores proactively

- Keep alternative sources for parts/components/chemicals handy to ensure that sourcing issues do not halt the production. Having multiple suppliers at the outset covers the immediate risks created in case of sourcing disruption at one end

- Invest in understanding and analyzing other operational, socio-political, natural or regulatory forces that may affect the suppliers’ capability to deliver

- Create a robust supply chain adaptation and a flexible risk management opportunity by opting for solutions that can map suppliers on multiple levels, create supply chain visibility and shape your business for proactive actions in such cases

Feel free to reach us at [email protected] , if you are considering a risk management solution or have more questions on what it means to implement one in your organization.

Want to learn how Resilinc can provide you the solutions to build a best-in-class supply chain resiliency program?

Sources:

Hanjin Company Website