As healthcare authorities worldwide struggle to contain the coronavirus outbreak, supply chain managers are also working on the front lines of the crisis. In several online roundtables held Jan. 30 through Feb. 3 for customers and partners, Resilinc senior executives discussed with public- and private-sector healthcare supply chain experts the challenges presented by the crisis that began in Wuhan, China. A video of the Resilinc webinar “Planning, Preparedness and Proactive Actions Updates for Coronavirus” can be found here.

Addressing Healthcare-related Shortages

During one of the roundtables, representatives from the World Health Organization, MIT Humanitarian Supply Chain Lab, Healthcare Ready, Resilinc’s Healthcare Transparency Initiative and others described a rapidly evolving scenario in which shortages of personal protective equipment (PPE) such as masks and hand sanitizer are the most immediate concern.

“The healthcare industry was already dealing with a shortage of gowns and other personal protective gear, and those are going to be highly exacerbated by the coronavirus crisis,” said Resilinc CEO Bindiya Vakil. Additionally, drug shortages are likely on the horizon because of the extensive sourcing of active pharmaceutical ingredients from the Wuhan region, said Vakil. She noted that Wuhan encompasses six industrial parks within what’s known as the Wuhan Biolake, which hosts manufacturers that produce bio-pharmaceuticals, medical devices and other medical products. Most of these industrial parks have been reportedly shut down due to the quarantine.

Prepare for Multiple Scenarios

Vakil recommended that manufacturers with suppliers in the region plan for a range of scenarios, with the average-case scenario mirroring the trajectory of the 2009 swine flu, which disrupted supply chains for three to six months. A best-case scenario would see the crisis resolved within a few weeks while the worst-case scenario could cause disruptions for up to nine months—essentially until an effective vaccine for the coronavirus is developed and distributed, according to Vakil.

“We’re not making any specific predictions nor issuing any guidance but sharing estimates…based on 10 years of experience and analyses of our real-time data from more than 100,000 suppliers,” she said. “We should get more clarity on the recovery and fatality rates associated with the virus in the next 2-3 weeks.”

Large Swath of Industries Affected

The 14 industries affected by the coronavirus crisis include the following:

- Aerospace

- Automotive

- General manufacturing

- Healthcare

- Consumer goods

- Consumer electronics

- Food and beverage

- Life sciences

- Industrial chemicals

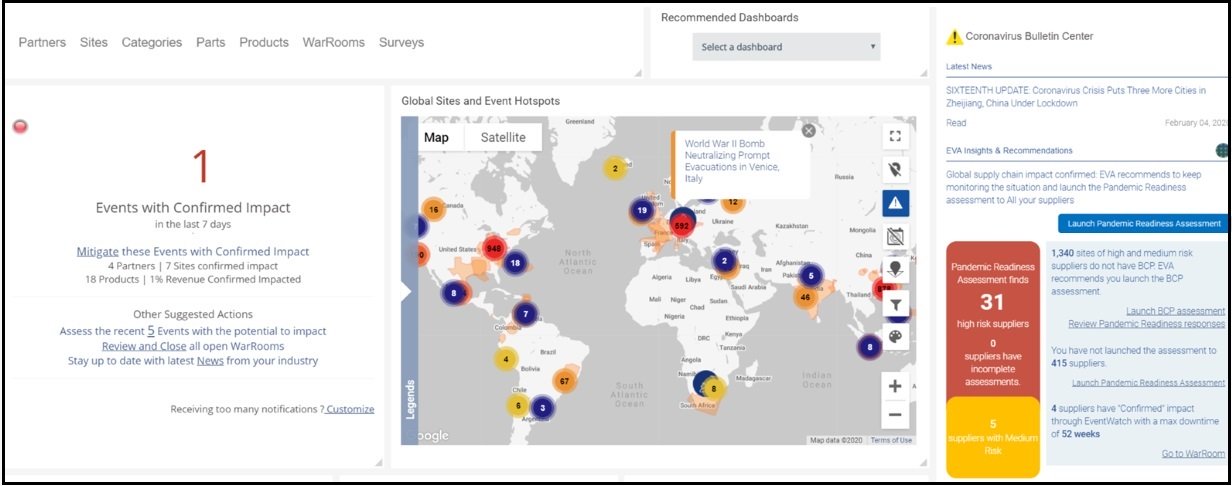

Resilinc’s data shows that 202 supplier firms operating 280 facilities within the Wuhan region have been disrupted by the Chinese government’s response to the outbreak, which has included an extension of the Lunar New Year vacation period and the shutdown of most transport systems.

As reported in business media, consumer electronics suppliers and their customers have been particularly hard hit. “We’re seeing disruptions in supplies of NAND flash memory media, optical electronics, semiconductors, active pharmaceutical ingredients and many other high-tech supplies,” said Vakil. “The city of Wuhan has long been a major transport and manufacturing hub, intricately connected to the global economy. And in recent years, private and public investment there has led to the development of manufacturing with high-end technological capabilities.”

Experience working in China will determine vulnerabilities

How effectively a large global company navigates this crisis will depend more on the maturity of its supply chain risk management (SCRM) program than the technological complexity of its products and suppliers, according to Vakil.

“This event will not affect every company equally,” she said. “For example, many companies that have experience in China routinely execute proactive build-ahead plans to obtain three to four weeks’ worth of extra inventory prior to the Chinese New Year because they know that their suppliers typically take about two to three weeks to come back to full capacity after the vacation break. That should provide a certain level of protection for many companies.”

Multi-tier supply chain visibility and mapping are key capabilities that provide invaluable supply chain resiliency benefits in this crisis. “Best practices in supply chain management today require mapping all your parts to supplier sites, including those of your sub-tier suppliers,” said Vakil. “Having this capability puts companies in an advantageous position in a crisis like this.”

Healthcare Supply Chains More at Risk

Healthcare supply chains are particularly sensitive — not only because of the health risks to patients when shortages occur, but also because the life sciences and pharmaceutical supply chains are highly regulated to ensure patient safety. “This makes alternate sourcing more challenging and underscores the vital importance of visibility into all tiers of supply chains,” said Graeme Dykes, Managing Director of the Healthcare Transparency Initiative (HTI). Formed by Resilinc and partners last year, HTI’s goal is to encourage transparency, accountability and cross-industry collaboration in healthcare supply chain management in order to avoid shortages that can impact patient care.

For procurement executives who are grappling with the coronavirus crisis without granular visibility into the multiple tiers of their supply chain, Vakil recommends some best practices that can still be enacted. “Be transparent and communicate proactively within your organization and with your customers,” she said. “And work out agreements with your colleagues across functions about what your dates and criteria will be for initiating emergency actions.”

Resilinc available to help

For non-Resilinc customers seeking supplier status, Vakil said that Resilinc can provide a Resiliency Data Service that utilizes publicly available information —as opposed to the proprietary supply chain data available to its customers. “Contact my team and we can do an NDA, and then send us the suppliers you’re interested in learning about. The data we can provide won’t cover the bases that our proprietary service provides, but it will get you in the ballpark.”

As the virus continues to inflict increasing suffering in the Wuhan region and elsewhere in China, Vakil underscored the vital importance of the work being done by healthcare supply chain managers. “Professionals in this field have been staying up night and day, looking for alternative sources and alternative sites for parts that originate in Wuhan and the Hubei region,” she said. “Our hearts go out to the people of Wuhan, the Hubei region and all of China. And our commitment is to do what we can to keep the parts and materials flowing and the supply chains running.”