Part 2: Planning your SCRM program

This is Part 2 of our four-part blog series based on Resilinc’s Ultimate Guide to Supply Chain Resiliency. For those just starting out, this series should help you leverage the lessons of COVID-19 to build support for investment in a robust SCRM program. If your company has a mature and well-function SCRM program, then these blogs can help you validate what you’re already doing and provide ideas for fine-tuning your program.

In Part 1: Introduction, we introduced helpful tips on starting the SCRM journey. In Part 2 we are outlining how to put a plan to paper. It starts with building a business case.

BUILD THE BUSINESS CASE

Key tasks in the Plan phase include developing a business case, creating service agreements with internal customers, defining metrics, and building a team and governance structure. Of these tasks, the most important is the business case, which is usually prepared in the form of a proposal to C-level leadership, category managers, unit leaders and other key stakeholders. To respect your busy managers’ time, keep the proposal brief and be sure it achieves the following:

- Clearly states the purpose and goals of the proposed SCRM initiative.

- Shows how the SCRM program aligns with company strategy (see the end of the Introduction for an example of how to link your company’s strategic objectives with the SCRM’s tactical objectives).

- Estimates return on investment (ROI) with a range of scenarios

- Responds to anticipated objections.

Of these elements, the most important is the analysis of potential ROI. To estimate the investment costs, include staff, training and technology services (such as cloud system subscription fees, IT consulting and software license) as well as ancillary costs like meetings and travel. (Yes, we will be traveling again!)

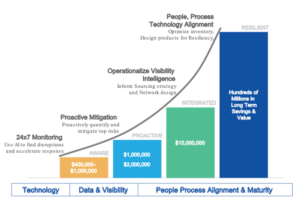

To generate credible ROI estimates, perform sensitivity analyses based on a range of scenarios from worst to best case. Historical data and staff memories about past supply chain disruptions can be used to build scenarios estimating how the SCRM can reduce the costs of managing future disruptions. However, not all the value produced by an SCRM is related to disruptive events. For example, companies that achieve high levels of maturity and visibility in their SCRM program can reduce their inventory buffers (over and above lead-time buffers). The chart below shows five of the top sources of ROI from an SCRM, including event-related savings and ongoing sources of value.

Better, Faster, More Accurate Decisions = ROI Realized

| Team efficiencies | Near term (1st year) | 10-15% | Ongoing |

| Raw material premium savings | Medium term (2nd year) | 15-20% | Event Related |

| Reduction in Freight expediting | Medium term (2nd year) | 5% | Event Related |

| Reduced inventory levels | Long term (3rd year) | 10-20% | Ongoing |

| Protected revenue | Long term (3rd year) | Event related |

Over the longer term, more intangible returns flow from a mature SCRM program, such as improved customers relations, the ability to design products for greater resiliency and even enhanced competitive positioning and brand value. Resilinc’s experience combined with market research show that a comprehensive SCRM program with robust supply chain visibility can yield up to $15 million annually for every $1 billion in sales. Estimating these higher-level values will take considerable thought and even some guesswork, but the illustration below can help.

Some other best practices to keep in mind: calculate ROI over a three-year period to allow for the program to mature; acknowledge that some risk mitigation and resiliency measures are already in place and include only anticipated incremental revenue and cost savings; and collaborate with stakeholders across functions (finance, sales, manufacturing, logistics etc.) to ensure leaders feel invested in the SCRM proposal and understand how the initiative can advance their interests.

ANTICIPATE AND ANSWER OBJECTIONS

The other point we’ll cover here is anticipating and handling objections from internal stakeholders. Resilinc’s experience reveals that the top five types of objections include:

Lack of incentives. Few supply chain executives and experts are financially incentivized to rigorously manage risk on an ongoing basis.

Perception that suppliers won’t collaborate. Historically, many suppliers have been reticent to share information that they fear may be used against them in financial negotiations.

Perceived high costs and conflicting objectives. Elements of a supply chain visibility program can seem at odds with cost-efficiency strategies such as lean inventory management.

Biases and assumptions. A common view within large OEMs is that operations will always save the day with an heroic “diving catch,” or that the commodities team will “gut” their way through the next disruption, thus making an SCRM program unnecessary.

Difficulty in valuing risk management. This widespread problem can make senior leaders reluctant to support the investment and internal change management required to develop a robust SCRM program.

The team developing the business case should take a realistic pulse of these and other objections they’re likely to encounter and address all anticipated objections proactively. There’s more guidance on how to do that—as well as other recommendations for the business case and the entire Plan phase—in the full Ultimate Guide.

Next week’s post will dive into the Implement phase of the journey to a resilient supply chain.