Welcome to part three of our AI in Supply Chain blog series. In this blog, we explore the different types of predictive AI models for supply chain risk management.

In our second AI blog of the series, Predictive AI vs. Generative Supply Chain AI, we looked at the difference between predictive AI and generative AI. Currently, Resilinc uses several predictive AI models in tracking purchase orders (POs) and commodities, autonomous mapping, risk-scoring models, and simulators. While these solutions all utilize predictive AI, they rely on different models, including regression models, time series forecasting, classification models, clustering models, recommendation models, and simulation models.

In this blog, we explore the models used in Resilinc’s predictive AI and explain how they help streamline supply chain risk management. We will also look at real-life use cases and applications for each model.

1. Regression Models: Predict Purchase Order Delays

What are regression models?

Regression models are utilized to predict continuous numerical values and are a fundamental concept in machine learning. In layman’s terms, these models help find the relationship between different variables, predicting how one variable will affect another.

How does Resilinc use regression models?

The AI that goes into our Purchase Order Delivery Delay Prediction Engine is a type of predictive model called a regression model. This engine leverages AI to identify how a supplier will perform by analyzing past events and on-time delivery data. Watch the video below to learn more about our Purchase Order Delivery Delay Prediction Engine.

Real Use Case for AI Regression Models in Supply Chain Risk Management

Let’s take, for example, a typhoon hitting the coast of China and see how our engine can help. In a typical scenario, a company reaches out to suppliers and begins talking to logistics and procurement after the typhoon strikes. In this case, the chances of a successful recovery are significantly reduced, even though the company focuses all its efforts on reacting to the disruption.

Instead, the company should be predictive rather than reactive. Using predictive AI, the company can estimate the expected delay that will be caused by the typhoon. Then, they can see what the associated revenue risk will be if parts don’t arrive on time. From there, the company can look at impact scenarios, take action based on past experience, and reroute carriers—all before the typhoon hits. This also frees up the company’s human experts so they can focus on developing more effective supply strategies.

2. Time Series Forecasting: Commodity Tracking and Predictions

What is time series forecasting?

Time Series Forecasting models forecast future values within a historical time series data set. This model looks at time-stamped data and makes observations about what will happen in the future. These predictions can then be used for strategic decision-making.

How does Resilinc use time series forecasting?

CommodityWatchAI is a predictive algorithm that combines time series forecasting and Resilinc’s proprietary data to predict commodity price fluctuations and supply constraints more than three months out. This allows companies to see what is in demand, source alternative materials, and negotiate new contracts with suppliers at opportunistic price points. Our Patent Pending model utilizes this technology to predict commodity trends across a wide range of commodities, including rare earth minerals, raw materials, gases, and metals.

Real Use Case for AI Time Series Forecasting in Supply Chain Risk Management

The ability to anticipate and navigate commodity price fluctuations is paramount in risk management. Let’s delve into a practical scenario with copper, a fundamental manufacturing component. Imagine there is a 20% surge in copper prices triggered by sudden geopolitical shifts—disrupting the supply chain. For supply chain professionals, predicting the current price amidst such volatility is akin to navigating through a storm without a compass.

This is where CommodityWatchAI can help. By analyzing historical disruptions and decoding intricate market patterns, the system predicts optimal times to either place procurement orders or exercise patience, waiting for more favorable conditions. By offering a proactive lens into future commodity prices, CommodityWatchAI equips organizations to turn supply chain challenges into strategic advantages, ensuring resilience and success in a competitive marketplace.

3. Classification Models: Supply Chain Disruption Alerts

What are classification models?

Classification models try to predict the correct label of a given data input. For example, a model could learn to predict whether or not an email is spam based on training data. This data would include inputs such as the subject line, sender’s email address, contents of the emails, links, and other relevant information that could help the AI determine the legitimacy of the email.

How does Resilinc use classification models?

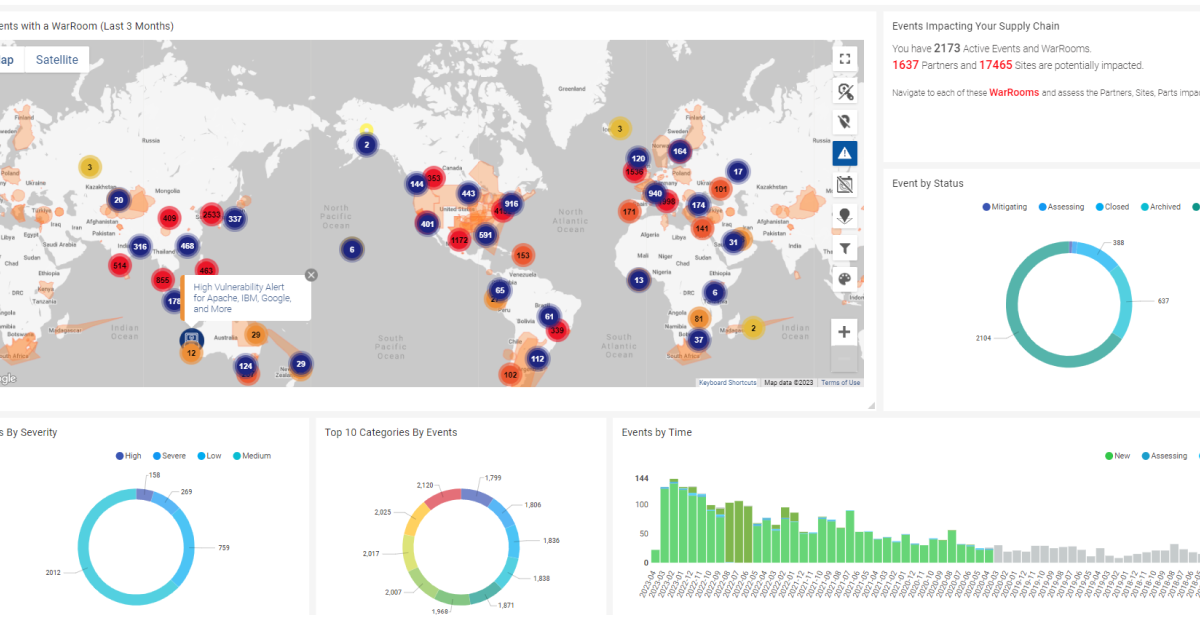

Resilinc uses classification models to determine whether or not news can be considered a supply chain disruption. EventWatchAI—Resilinc’s supply chain disruption alert platform— monitors text-based electronic media worldwide 24/7, from over 104 million sources in 108 languages. Today, using AI, we monitor and alert customers about 400 scenarios and around 40 event disruption types—receiving about 8,000,000 rows of data daily. Without a proper, robust AI-based system, dealing with this vast amount of data would be impossible.

Real Use Case for AI Classification Models in Supply Chain Risk Management

Picture a scenario where a supplier, three tiers deep in the supply chain, declares bankruptcy. This is more than a financial setback. It triggers a domino effect, disrupting operations, challenging logistics, and posing financial risks to all entities connected in the supply chain web. If your company works with this supplier, it may be difficult to find news about their bankruptcy. From millions of news feeds, filtering for this one piece of crucial news becomes a very difficult task.

Resilinc’s AI classification model, EventWatchAI, acts as a proactive sentinel, classifying data related to the supplier’s bankruptcy and triggering alerts to relevant suppliers and companies. These alerts serve as early warnings, providing decision-makers with timely insights to navigate the impending challenges.

Armed with real-time insights, supply chain professionals can make informed decisions. Whether it involves identifying alternative suppliers, reassessing procurement strategies, or devising contingency plans, the proactive approach facilitated by AI classifications enables a swift and strategic response, ensuring sustained success in the face of financial uncertainties.

4. Recommendation Models: Supplier Network Predictions

What are recommendation models?

Recommendation models analyze the relationship between products and users and make personalized recommendations based on past data. Outside of supply chain, recommendation models have been used by Uber to suggest foods that customers are likely to order. Pinterest also uses an algorithm to suggest content that users will enjoy.

How does Resilinc use recommendation models?

Our Autonomous AI Mapping uses a type of recommendation model called Graph Neural Networks (GNNs). This AI is tailored for data structures as graphs, such as knowledge graphs. Using AI, this solution helps companies quickly gain visibility into where suppliers’ factories are located worldwide by leveraging Resilinc’s supplier intelligence. Resilinc has been building and perfecting our dataset for over a decade from websites, press releases, bills of lading, and public domain data sources.

Real Use Case for AI Recommendation Models in Supply Chain Risk Management

When a primary supplier faces an unexpected challenge, the ability to swiftly identify and connect with alternate suppliers becomes not just a strategic advantage but a necessity. Consider the recent global semiconductor shortage, which sent shockwaves through various industries heavily reliant on electronic components. In this scenario, the disruption to a primary semiconductor supplier triggered a cascade effect. Manufacturers faced production halts, impacting delivery schedules and eventually leading to financial losses.

Resilinc’s Autonomous AI Mapping serves as a strategic ally in navigating disruptions like this. By predicting alternate suppliers, it transforms potential crises into opportunities for adaptability and resilience. Supply chain professionals armed with this technology can make informed decisions, ensuring minimal disruptions and optimizing operations even in the face of unforeseen challenges.

5. Simulation Models: Natural Disaster Supply Chain Disruptions

What are simulation models?

Simulations model how a system will behave. Using a simulation model, it is possible to conduct tests, analyze future impacts, and create plans based on findings.

How does Resilinc use simulation models?

Resilinc uses simulation models for simulating real-world scenarios such as extreme weather like hurricanes and other disruptive events.

Real Use Case for AI Simulation Models in Supply Chain Risk Management

The impact of a hurricane on the supply chain can be extensive, leading to factory closures, transportation delays, and disruptions in the delivery of goods. The ability to forecast and prepare for these events is crucial for maintaining a resilient supply chain. Enter Resilinc’s Hurricane Simulation Model, a powerful tool that allows supply chain professionals to simulate and analyze the potential effects of a hurricane on their operations. This virtual crystal ball leverages historical weather data, geographical information, and logistics parameters to create realistic scenarios, enabling companies to explore ‘what-if’ situations and formulate effective contingency plans.

Consider a scenario where a manufacturing facility located in a hurricane-prone region relies on a complex network of suppliers, distributors, and logistics providers. The Hurricane Simulation Model emerges as a strategic asset in preparing for the unpredictable. By allowing companies to explore different scenarios and assess the potential impact of hurricanes, it empowers supply chain professionals to make informed decisions and implement proactive measures to mitigate risks.

***

How Can AI Help You with Supply Chain Risk Management?

Responding quickly and efficiently is critical to managing risk in the world of supply chain. With the power of AI, companies can mitigate risks faster and gain a competitive advantage over competitors who have not invested in the latest technology.

Ready to harness Resilinc’s AI and data-backed solutions to respond to supply chain disruptions quickly and mitigate risk? We are committed to helping you achieve your supply chain resiliency goals by giving you the tools necessary to respond, recover, and turn risk into an opportunity. See how our AI-powered and data-driven solutions can help your company become more resilient. Request a demo today.