From antifragile supply chains to predictive AI and the need for more multi-value supply chains—the annual Gartner Supply Chain Symposium/Xpo™ conference left attendees and key C-Suite decision makers discussing trends and technology innovations contributing to the modernization of global supply chains.

Held May 6-8 at the Walt Disney World® Swan Resort near Orlando, the event brought together over 4,000 attendees who networked, knowledge shared, and gained exclusive Gartner insights and the latest market research shaping the future of supply chain management.

As C-Suite leaders continue to face the dual challenges of growing the business while responding to the challenges of an evolving market, discussions around cost management, the need for greater alternative sourcing, and use of supply chain lifecycle management approaches were resounding themes at the event.

Here are our key learnings and top 5 takeaways from this year’s Gartner Supply Chain Symposium/Xpo.

1. Antifragile supply chains thrive in uncertainty

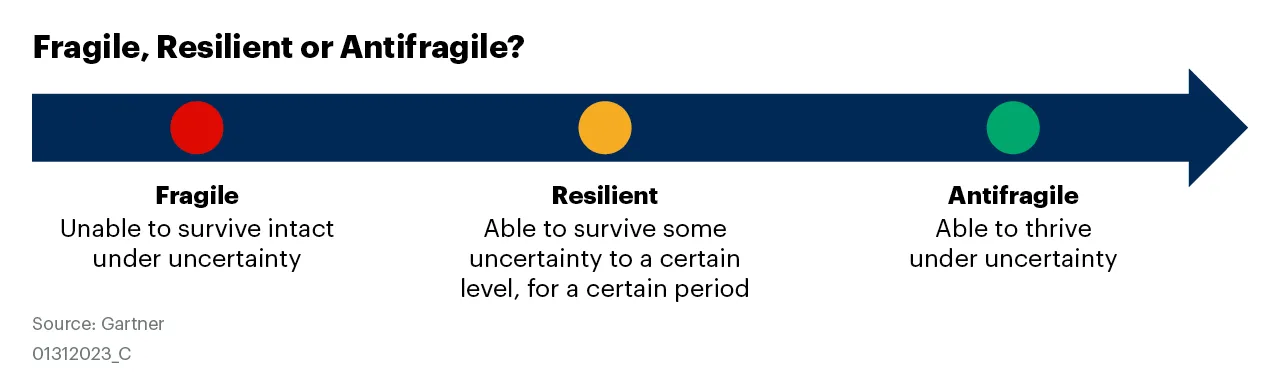

There was one resounding buzzword at the event this year: antifragility. In the day one opening keynote, “Move to Drive—Owning Supply Chain’s Value,” Gartner’s VP Analyst Tom Enright covered the topic of antifragility and how, for the past few years, forces outside of supply chain organizations dictated when and how the supply chain adds value. Now, companies have the opportunities to embrace uncertainty and use it to add value to the supply chain, by becoming antifragile. Gartner describes antifragility as a state beyond resiliency, where companies thrive in uncertainty. It is the next frontier beyond resiliency and a competitive advantage for companies who achieve it.

In another session, Gartner’s managing VP, John Dixon, explored the topic further. In “The Antifragile Supply Chain—Thriving Due to Uncertainty,” Dixon discussed the crucial role of embracing uncertainty, experimentation, and learning in becoming antifragile. As companies’ supply chains continue to evolve, leveraging an antifragile approach as a cost-competitive differentiator to proactively plan for uncertainty and scarce resources will continue to grow as well.

In another session, Gartner’s managing VP, John Dixon, explored the topic further. In “The Antifragile Supply Chain—Thriving Due to Uncertainty,” Dixon discussed the crucial role of embracing uncertainty, experimentation, and learning in becoming antifragile. As companies’ supply chains continue to evolve, leveraging an antifragile approach as a cost-competitive differentiator to proactively plan for uncertainty and scarce resources will continue to grow as well.

2. Decision makers look to multi-value supply chain initiatives

Cost management continues to be the number one priority in supply chain in 2024. Supply chain professionals are looking for new ways to extract value from the supply chain, but they must know when and where to drive different kinds of value. Enright explored three different value segments: low-cost-focused, sustainability-focused, and innovation-focused. Each has benefits and tradeoffs; the innovation-focused segment is risky but yields the highest commercial innovation.

On day two, VP Analyst at Gartner Ken Chadwick, explored how companies yield ROI from digital tech investments. In his session, “CEO Concerns 2024—Implications and Actions for CSCOs”, Chadwick explained that effective companies are being patient with tech investments in order to best reap the ROI benefits of supply chain risk management technology. The same takeaway rang true at the Resilinc booth, as many attendees questioned and calculated exactly how much supply chain cost savings they could yield by entering such parameters as annual material costs, annual unplanned freight fees, and more into the Resilinc ROI calculator.

3. Predictive AI is the next frontier for Generative and General AI

The fear of AI taking jobs has subsided, as professionals see AI and generative AI as more of a mainstream enabler of efficiency. While AI’s maturity level is still very low, decision-makers still have ample time and opportunity to get to market with REVA and DVI-AI, automated playbooks, WarRooms, and similar AI-based technology.

C-Suite decision makers who adopted AI into their business practices continue to see AI as a competitive differentiator. Still, only conceptually at this point—we haven’t seen any major use cases that publicly resonate just yet. More than 60% of the push to embed AI into supply chain processes is coming from the C-suite for productivity, efficiency and competitive advantage.

Common use cases for Gen AI in supply chain include:

- Category updating information

- Building resiliency plans into supply base

- Using contract data to see risks in contracts and overall supplier risk

- Taking contract data and rolling it into SCRM process

As Generative AI becomes more accepted, Predictive AI will be the next frontier for AI adoption in supply chain. Learn more in our blog: Predictive AI vs. Generative AI in Supply Chain Management.

4. Supply chain risk management needs greater integration into critical business processes

Companies with global supply chains utilize a variety of different supply chain management tools. As a result, fragmented, siloed use of different tools is still a predominant challenge for common processes such as S&OP, allocation strategy, safety stock planning, sourcing strategy, inventory management, and logistics strategy.

Once clear-cut distinctions, the lines between third-party risk management (TPRM) and supply chain risk management (SCRM) are starting to blur. In fact, Resilinc team members fielded numerous questions about better leveraging automated data. Attendees wanted to learn more about integrating risk data into critical business processes. It is important to note that the market moves faster than the industry, and it will be a while before we see this shift in complete, holistic end-user adoption of end-to-end SCRM and supply chain resiliency solutions.

5. Companies and suppliers look to sub-tier- and part-site-mapping for proactive risk intelligence

Companies are now looking to scale beyond disruption monitoring and instead apply a more proactive approach by leveraging sub-tier, part-site mapping data. There is an industry-wide shift towards better decision-making and a newfound interest in building supply chain resiliency through proactively using risk intelligence.

This shift is due in part to companies’ constant need to predict disruptions, such as ESG regulations, climate change disruptions, and ever-changing geopolitical climates. Megatrends like—geopolitics, climate change, cyber attacks, ESG, and labor issues—will continue to impact global supply chains in both the near- and long-term. Discover insights into these megatrends in our 2023 annual supply chain report.

Now is the time to invest in your supply chain strategy

From discussions on antifragility and multi-value supply chain initiatives to the growing importance of predictive AI and integrated risk management, it’s evident that organizations are seeking proactive approaches to mitigate risks and drive value throughout their supply chains.

As we reflect on the invaluable insights from this event, we invite you to explore how Resilinc’s Multi-Tier Mapping® can empower your organization to build an antifragile and agile supply chain. Proactively map your suppliers down to the part-site level using Resilinc’s 12+ years of supplier-validated data—and protect your supply chain from the disruptions of the future. Learn more about Resilinc’s Multi-Tier Mapping solution.