On Aug. 24 at 3:20 a.m. Pacific Time, a 6.0 magnitude earthquake shook Northern California, injuring many people, damaging buildings and knocking out power and water services around Napa.

Though the Bay Area region is prone to this kind of natural phenomenon, it’s been a while since locals felt something this significant. The last major earthquake in the Bay Area was the 6.9 Loma Prieta earthquake in 1989. Luckily, too, in comparison to other past tremors, the Napa earthquake was moderate.

But, still, it was an event that could have quickly turned in a wide-scale disruption. More importantly, it reveals how vulnerable supply chains are when Mother Nature is involved and how quickly you have to spring into action to get the situation under control. It is the perfect example of a supply chain resiliency case study.

For those of you who assess risk on a regular basis, you understand how critical it is to stop everything you’re doing when an event happens. In this case, literally taking the “wake-up” call, where you may have got out of bed immediately to analyze the situation and potential impact. That’s what happened as soon as our team felt the shake–our event monitoring team began scanning the newsfeeds, assessing the situation, alerting clients about what was happening and individually notifying our EventWatch subscribers of the potential impact to facilities in their supply chain. We did all this within 90 minutes of the earthquake’s occurrence.

We knew this would be vital information for many of our customers doing business in the region. Also, because the earthquake happened in the early morning hours on a Sunday, we knew risk mitigation executives would have to be ready to report to senior management and get the action plan moving by 8 a.m. Monday morning.

Since we were already at work gathering information and looking at the scope and scale of damage in the aftermath, Resilinc subscribers got a break. They got to sleep in because our 24×7 event monitoring services were doing the work for them. So while our subscribers may have woken up to a potentially disruptive situation, they did not have to spend their Sunday working on collecting the information or running the initial event analysis. They could take our alerts and start mapping out what-if scenarios, think about alternate sourcing plans and get their head around long-term risk-avoidance issues.

You Never Know When Disaster Will Strike. But, You Can Keep Your Supply Chain Moving When it Does

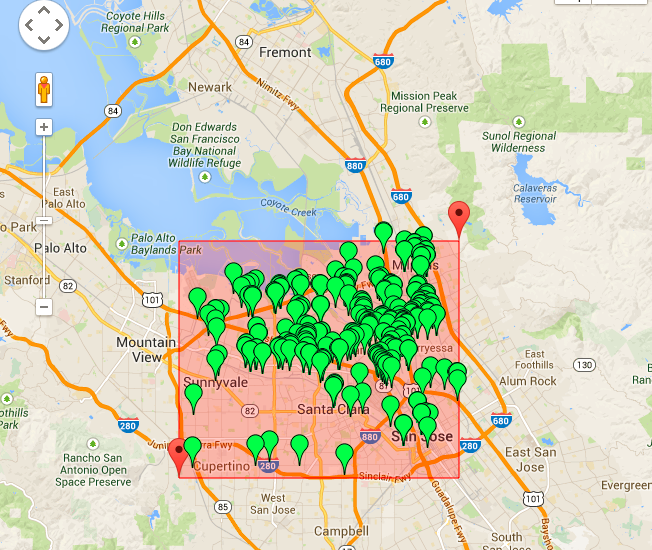

In 2011, the world witnessed how the earthquake in Japan and resulting tsunami had devastating effects to communities and global supply chains in electronics, automotive and life science industries. In contrast, the recent Napa earthquake was comparatively mild, but it occurred along a fault thought to be inactive. Some scientists are concerned that the release of stress by this fault could have increased the stress on the Hayward Fault, a major fault that runs east of the San Francisco Bay from San Jose to San Rafael. This area is densely populated with people and companies, and an earthquake in that area could have critical and direct impact on the automotive, electronics and life science supply chains (See map).

Although Resilinc has assessed the North Bay earthquake as having a small impact on the supply chain, an event 60 miles south in San Jose could impact as many as 140 sites. Should an event occur here or anywhere, for that matter, Resilinc’s services reduce the analysis time for our customers by instantly providing notification of the sites potentially impacted as well as the part numbers. This gives our customers a head start on procuring material to keep their production online, and before supplies become scarce and prices increase.

The early morning North Bay earthquake was another reminder for the industry that things could change overnight. For some people, the news meant long hours trying to make sense of what was happening where and scrambling to stay up to date. Others, though, relied on our mapping and constant monitoring services, and got to spend their time mitigating the weekend rather than risk.

What’s your wake up going to be?

Find out more about Resilinc’s event monitoring capabilities.

Charlotte Hicks is a Product Manager for Resilinc, specializing in Life Science.